While at nyuad.space, I worked on a Hold Down and Release Mechanism (HDRM) in collaboration with NASA JPL’s University Crowdsourcing Initiative (JUCI). This project focused on creating a mechanically and electrically redundant system for small satellite payloads. The design emphasized reliability and reusability for pre-flight testing and deployment.

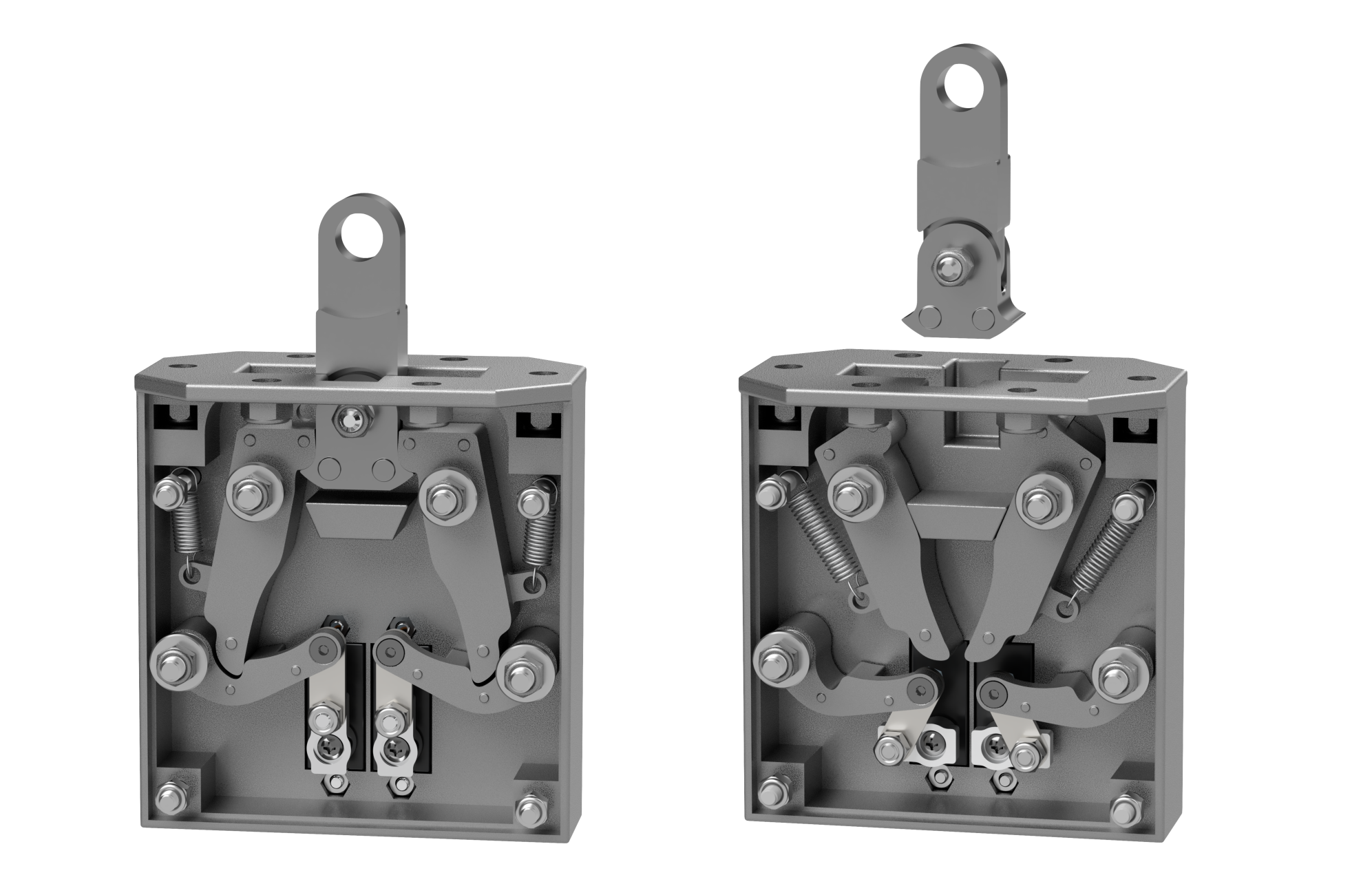

The hold-down and release mechanism was made as part of NASA JPL’s University Crowdsourcing Initiative (JUCI). The team set out to make a mechanically and electrically redundant HDRM for small satellites and payloads. To that end, the team created a dual over-center latch system, with a pin that could pivot to allow for release if either latch was released. The HDRM was designed not to have any consumable parts and to be easily reset and reused for pre-flight testing.

When designing the HDRM, the team opted to avoid physical construction and iteration, instead utilizing simulation and CAD to rapidly iterate through designs and tests. Once complete, parts were manufactured by fabricators in titanium and stainless steel, using machining and 3D printing. When the parts arrived in Abu Dhabi, we had the first functional prototypes of the HDRM.

Two prototypes were made, which were used for stage separation in HALOSHIP. The prototypes functioned flawlessly in their first complete test, holding the stages together throughout the launch and deploying the main and drogue chute when commanded.

After being tested the prototypes and a display model were presented to our mentor’s at JPL in California, with future improvements discussed.

Check out the nyuad.space’s website Here

JPL’s clean room